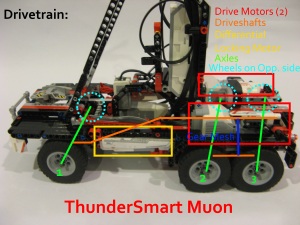

I would like to share with you my latest project, the ThunderSmart Muon! The ThunderSmart Muon is an EV3 creation. It is a 6-wheel drive, supersize variant of the ThunderSmart III, complete with automatic locking differentials and advanced programming to make it a formidable off-roader!

Click here for a video of the TSM in action: https://youtu.be/TkCjKZLiru0

Naming and Styling

You may be wondering how the ThunderSmart Muon got its name. Well, a muon is basically an electron, but about 200 time more massive. Similarly, the ThunderSmart Muon is a more massive version of the ThunderSmart III, built with an extra axle and 722 LEGO Technic parts! Now, I’ll discuss the styling; I was trying to make the TSM look a little different from the TSIII, but ended up with something that looks like a bigger TSIII. (Not that I’m complaining!) The TSM has a lot of flat surfaces to give it a musclecar look. The overall silhouette is of a pickup truck. Details such as a push-guard and a winch give a more rugged appearance to the front bumper, and signature styling details such as the lightning rod on the roof and the Thundercharger on the hood are retained. My inspiration for building the TSM came when I saw the Mercedes-Benz AMG 6×6 G-wagen in a magazine a little over a year ago. I finally decided to build a 6WD because I got bored of 4WD. 🙂

Steering

The steering is powered by an EV3 Medium motor, offset to the right side of the vehicle. The power is routed onto the centerline by a pair of 16-tooth gears. Then, a 12-tooth gear meshes with the rack gear, which is transversely mounted and directly turns both wheels. (There is none of that innovative longitudinal rack system here, as it wasn’t needed.) Aside from the different rack gear position, the architecture of the TSM’s steering is identical to that of the TSIII. Thanks to the programming, the steering is return-to-center in each RC program. Universal joints on the front axle allow the TSM to continue to power the front wheels while turning.

Drivetrain

This is by far the most interesting and unique part of the TSM. First of all, the drive motors are two EV3 Large motors and are located up high and far back in the vehicle, where the “pickup bed” is. The reason for this is to be able to power all 6 wheels while eliminating as many gear meshes as possible. My original design had the motors located in the middle and down low, like in the TSIII, and the rearmost axle got its power off of the middle axle, after the middle one got it directly from the drive motors. I soon realized this was a terrible design, as axle 3 is parasitic off of axle 2. Now, however, the drive motors start up high. Like before, the power from the hard-coupled drive motors is redirected 90 degrees to a shaft running lengthwise at a 3:1 gear ratio. However, off of this shaft is a pair of 24-tooth gears, which transfer the power down between the rear two axles, so neither is parasitic. This shaft also continues to the front, where Universal and CV joints transfer power down to the front axle without a power-consuming gear mesh. Each of the three axles have a differential, but the rear two are a little special. Continue to the next section for more on the differentials!

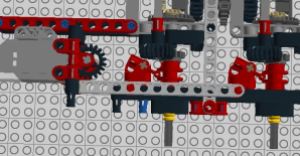

Locking Differentials

One feature that I’m very excited to share with you is that the TSM features my first-ever locking differential system! The differentials on the two rearmost axles automatically lock. How do they do this? First, an EV3 Medium motor on the left side of the vehicle routes its power through a 90 degree connection on a 1.67:1 gear ratio. Then, a lever pushes/pulls a rod, which in turn pushes/pulls another lever, which rotates the red gear fork to slide a synchro in and out of a 16 tooth clutch gear on one side of the differential. Now, this is where the magic happens! When the synchro is not slid into the clutch gear, the differential is open. When the synchro slides into the clutch gear, this rigidly links the left half-shaft to a solid shaft running above the differential, which is already linked to the right half shaft through a rigid gear mesh; so, the two half shafts become locked together through the shaft above. This forces the two wheels on that axle to rotate at the same speed, which makes turning impossible, but prevents the differential’s power from taking the path of least resistance when a wheel leaves the ground whilst crawling over bumps, which would and halt the whole car. The locking is controlled automatically by one of four programs, which I’ll explain in the next section!

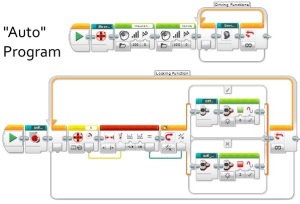

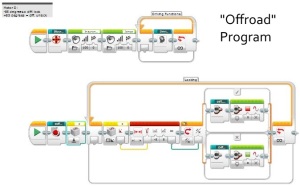

Programs

I have written four programs for the TSM, all of which are variants of one another. They are all fully-functional RC programs, but they differ by the conditions in which they lock the differential. In “Auto,” the differential locks when you’re driving straight, then unlocks when you give the command to steer. In “Offroad,” the differential remains unlocked until the gyro sensor (located under seat) detects a tilt of +/- 5 degrees. In “Race,” the differential is open at all times; this is because the locking motor steals power from the drivetrain, so it is deactivated to increase the TSM’s speed. Lastly, in “Police” mode, the TSM becomes a police car; the program is essentially the same as “Auto,” with the addition of flashing brick LED’s and an audible siren.

Conclusion

The ThunderSmart Muon was certainly a very interesting build! It took me a few redesigns to get it to work, but now I feel the sweet satisfaction of driving my first 6WD vehicle! I wish it had a little more power, because it is heavy; and it’s not particularly fast, with an official lap time of 36.27 seconds; but it is a mechanical feat and a real novel experience to drive! Thank you for reading about the ThunderSmart Muon, and see you next time!